Centerless Grinders

- home

- product

- Centerless Grinders

service menu

recent posts

Get in Touch with TSG

Reach out to us today, and let’s work together to enhance your productivity with cutting-edge grinding technology. Your success starts with TSG!

- tsgmc@naver.com

- +82-55-286-5586

TCG-150&TCG200: Centerless grinder

The TCG-150&TCG-200 Centerless Grinder are optimized for in-feed grinding of small-sized components, offering a compact yet robust solution for high-precision production. Designed with a separated coolant passage and machine frame, it effectively minimizes thermal deformation, ensuring stable accuracy even during continuous operation.

- Minimized thermal deformation by deviding machine frame and coolant passage

- High stiffness G/W and R/W spindle

- Applying cylindrical roller bearing at G/W and R/W

- Easy to set due to the wider length of R/W for thru-feed grinding

- Suitable for in-feed and thru-feed grinding for small size products

- Keep clean by eliminating hydraulic tank

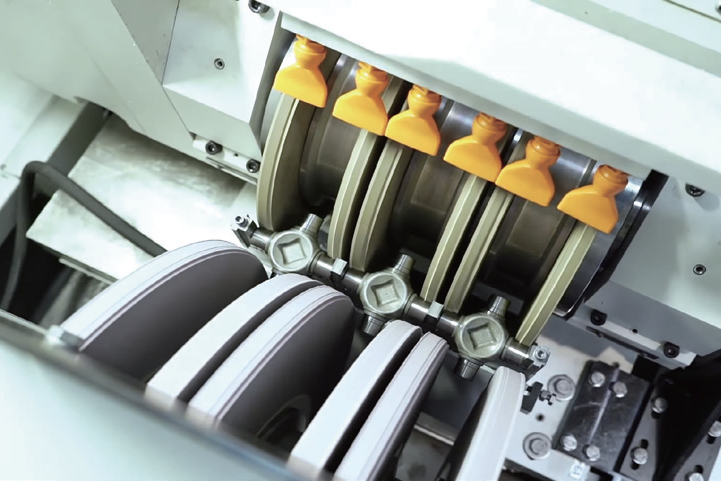

- Valve spool, Comp’piston, Lever, Cam bolt

specifications

| ITEM | TCG‐150 | TCG‐200 | ||

|---|---|---|---|---|

| Working range | Out-diameter | Ø1.5 ~ Ø40mm | Ø1.5 ~ Ø50mm | |

| In-feed length | Max. 150mm | Max. 200mm | ||

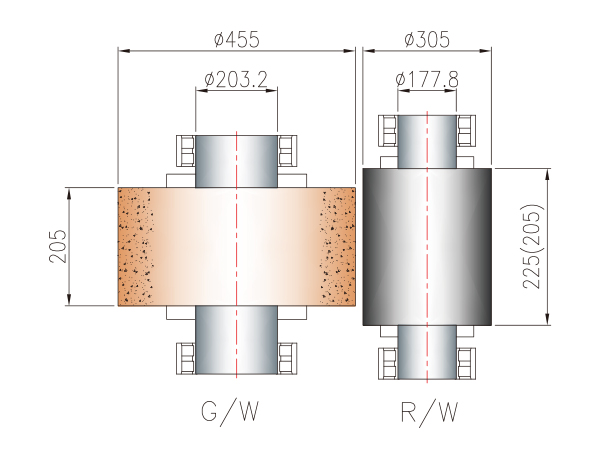

| Grinding wheel | O.D X Width X I.D | Ø455 x 150 x Ø228.6mm | Ø455 x 205 x Ø203.2mm | |

| Supporting type | Cantilever | Dual supporting | ||

| Regulating wheel | O.D x Width x I.D | Ø305 x 150 x Ø177.8mm | Ø305 x 205 x Ø177.8mm | |

| Supporting type | Dual supporting | Dual supporting | ||

| Speed modulating | Inverter | Inverter | ||

| Dresser | G/W | G/W traverse | Speed control motor | Speed control motor |

| Dress advance | Servo motor / Manual | Servo motor / Manual | ||

| R/W | R/W traverse | Speed control motor | Speed control motor | |

| Dress advance | Servo motor / Manual | Servo motor / Manual | ||

| Tilting angle of R/W | -2º ~ +5º | -2º ~ +5º | ||

| Motor | G/W driving | 7.5kw · 11kw · 15kw, 4p | 7.5kw · 11kw · 15kw, 4p | |

| R/W driving | 0.75kw, 6p, Inverter | 0.75kw, 6p, Inverter | ||

| Floor Size | 1,900 x 1,520mm | 1,900 x 1,520mm | ||

| Weight | 3,700kg | 4,300kg | ||

In-feed grinding & measuring

- Measure both end dimensions of the machined part and feed the values back to the equipment.

In-feed grinding

- Infeed grinding which processes only a portion of the workpiece

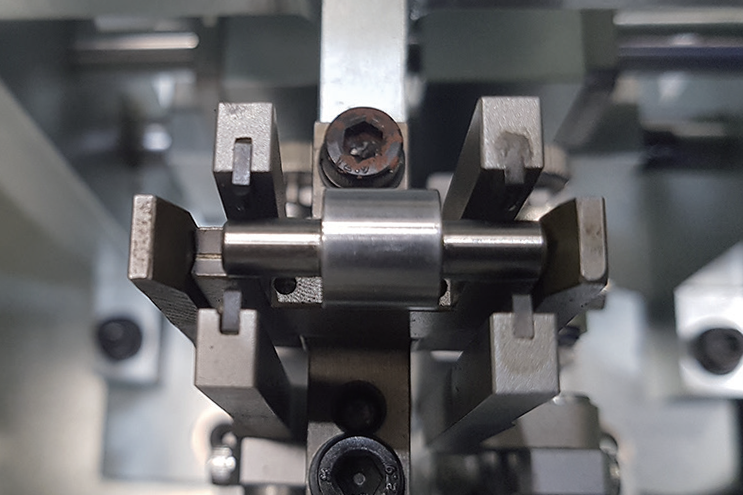

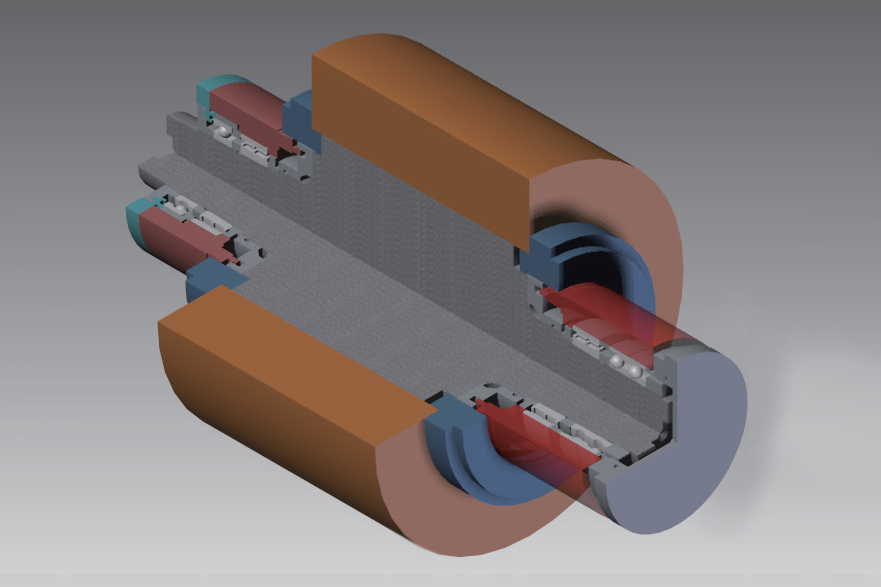

Double-ended G/W, R/W SPINDLE

Supported by ultra-precision double-row cylindrical roller bearings

- Maximized rigidity: The gap in the diametric direction is close to “Zero”, so there is little displacement due to grinding resistance and semi-finishing is possible

- Stable rotation accuracy: By minimizing spindle shaking, machining efficiency and machining accuracy are dramatically improved

- Minimum temperature rise: Even when operating continuously for 24 hours, the temperature rise is less than 10℃, so there is no change due to heat generation

- Easy lubricant management: Lubrication is grease-sealed, so refueling is unnecessary

- Easy maintenance: Spindle units are compatible, and bearing replacement is easy.

Dual supported wheel spindle (G/W, R/W)

TCG-200B & TCG-250: Centerless grinder

The TCG-200B & TCG-250 Centerless Grinder are engineered for both in-feed and thru-feed grinding, making it ideal for medium and small-sized components. Built with dual-end supported spindles for both the grinding (G/W) and regulating wheels (R/W), the machine ensures exceptional stiffness and precision, even under heavy-duty operation.

- High stiffness G/W and R/W spindle

- Applyung cylindrical roller bearing at G/W and R/W

- High stiffness grinding

- Keep clean by eliminating hydraulic tank

- Rocker arm Roller, Comp’shaft, H.J spider

specifications

| ITEM | TCG‐200B | TCG‐250 | ||

|---|---|---|---|---|

| Working range | Out-diameter | Ø2 ~ Ø120mm | Ø2 ~ Ø120mm | |

| In-feed length | Max. 200mm | Max. 250mm | ||

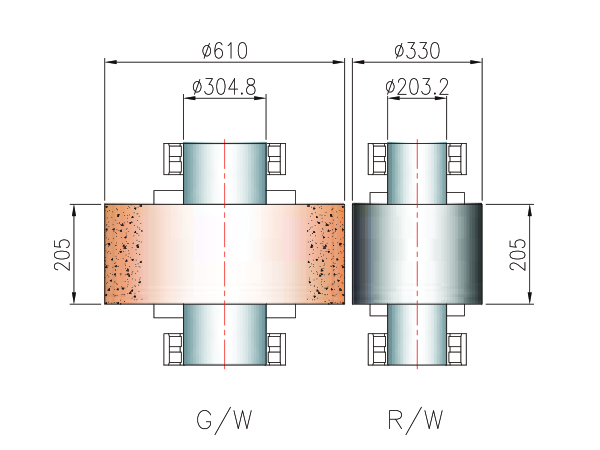

| Grinding wheel | O.D X Width X I.D | Ø610 x 205 x Ø304.8mm | Ø610 x 255 x Ø304.8mm | |

| Supporting type | Dual supporting | Cantilever | ||

| Regulating wheel | O.D x Width x I.D | Ø330 x 205 x Ø203.2mm | Ø330 x 255 x Ø203.2mm | |

| Supporting type | Dual supporting | Dual supporting | ||

| Speed modulating | Inverter | Inverter | ||

| Dresser | G/W | G/W traverse | Speed control motor | Speed control motor |

| Dress advance | Servo motor / Manual | Servo motor / Manual | ||

| R/W | R/W traverse | Speed control motor | Speed control motor | |

| Dress advance | Manual | Manual | ||

| Tilting angle of R/W | -2º ~ +5º | -2º ~ +5º | ||

| Motor | G/W driving | 11kw, 4p | 15kw, 4p | |

| R/W driving | 1.5kw, 6p, Inverter | 1.5kw, 6p, Inverter | ||

| Floor Size | 3,040 x 1,920mm | 3,040 x 1,920mm | ||

| Weight | 6,800kg | 6,800kg | ||

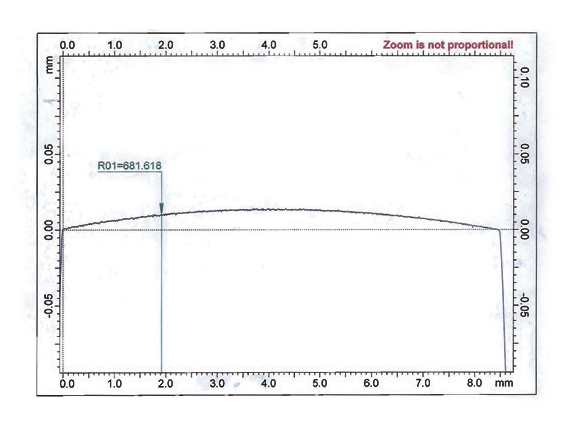

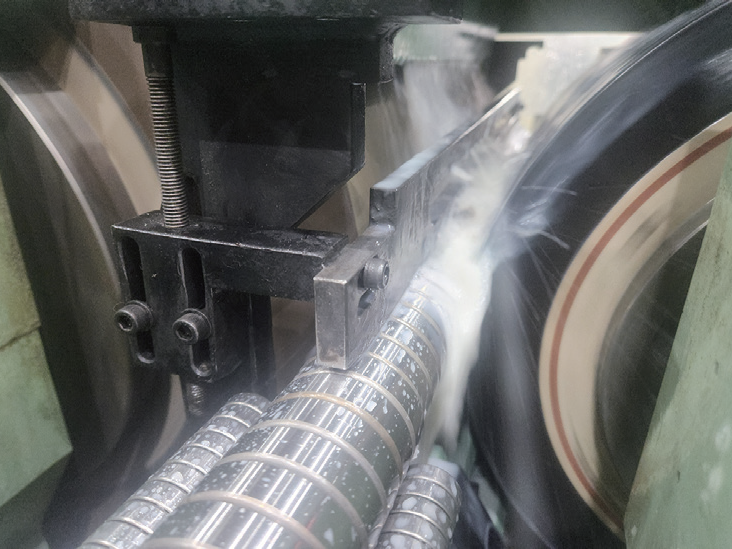

Crowning Shape Processing in Thru-Feed Grinding

- Thru-feed grinding the Rocker arm roller outer diameter with full crowning shape

- Crowning amount: 0.015 / 10 mm

In-feed grinding

- Depending on the size of the workpiece, multiple workpieces can be processed simultaneously.

Double-ended G/W, R/W SPINDLE

Supported by ultra-precision double-row cylindrical roller bearings

- Maximized rigidity: The gap in the diametric direction is close to “Zero”, so there is little displacement due to grinding resistance and semi-finishing is possible

- Stable rotation accuracy: By minimizing spindle shaking, machining efficiency and machining accuracy are dramatically improved

- Minimum temperature rise: Even when operating continuously for 24 hours, the temperature rise is less than 10℃, so there is no change due to heat generation

- Easy lubricant management: Lubrication is grease-sealed, so refueling is unnecessary

- Easy maintenance: Spindle units are compatible, and bearing replacement is easy.

Dual supported wheel spindle (G/W, R/W)

TCG-300 & TCG-400: Centerless grinder

The TCG-300 / TCG-400 Centerless Grinders are engineered for high-productivity in-feed grinding of medium to large-sized components. With grinding (G/W) and regulating (R/W) wheel spindles supported at both ends, these machines provide exceptional stiffness and long-term reliability. The use of cylindrical roller bearings further enhances durability and grinding performance.

- Minimized thermal deformation by deviding machine frame and coolant passage

- High stiffness G/W R/W spindle result from both ends supporting

- Applying cylindrical roller bearing at G/W and R/W

- High stiffness grinding

- Keep clean by eliminating hydraulic tank

- Bearing race, In put shaft, Scroll shaft

specifications

| ITEM | TCG‐300 | TCG‐400 | ||

|---|---|---|---|---|

| Working range | Out-diameter | Ø3 ~ Ø150mm | Ø3 ~ Ø150mm | |

| In-feed length | Max. 300mm | Max. 400mm | ||

| Grinding wheel | O.D X Width X I.D | Ø610 x 305 x Ø304.8mm | Ø610 x 405 x Ø304.8mm | |

| Supporting type | Dual supporting | Cantilever | ||

| Regulating wheel | O.D x Width x I.D | Ø330 x 325 x Ø203.2mm | Ø330 x 405 x Ø203.2mm | |

| Supporting type | Dual supporting | Dual supporting | ||

| Speed modulating | Inverter | Inverter | ||

| Dresser | G/W | G/W traverse | Speed control motor | Speed control motor |

| Dress advance | Servo motor / Manual | Servo motor / Manual | ||

| R/W | R/W traverse | Speed control motor | Speed control motor | |

| Dress advance | Manual | Manual | ||

| Tilting angle of R/W | -2º ~ +5º | -2º ~ +5º | ||

| Motor | G/W driving | 15kw · 22kw, 4p | 22kw · 30kw · 37kw, 4p | |

| R/W driving | 1.5kw, 6p, Inverter | 1.5kw, 6p, Inverter | ||

| Floor Size | 3,040 x 1,920mm | 3,040 x 1,920mm | ||

| Weight | 7,000kg | 8,000kg | ||

Double-ended G/W, R/W SPINDLE

Supported by ultra-precision double-row cylindrical roller bearings

- Maximized rigidity: The gap in the diametric direction is close to “Zero”, so there is little displacement due to grinding resistance and semi-finishing is possible

- Stable rotation accuracy: By minimizing spindle shaking, machining efficiency and machining accuracy are dramatically improved

- Minimum temperature rise: Even when operating continuously for 24 hours, the temperature rise is less than 10℃, so there is no change due to heat generation

- Easy lubricant management: Lubrication is grease-sealed, so refueling is unnecessary

- Easy maintenance: Spindle units are compatible, and bearing replacement is easy.

Dual supported wheel spindle (G/W, R/W)

Both ends supported grinding wheel spindle

- Maintaining high rigidity by applying cylindrical roller bearing

Thru-feed grinding for processing workpieces supplied continuously

- Effective for heavy-duty grinding and mass production