retrofit

- home

- service

- retrofit

service menu

recent posts

Get in Touch with TSG

Reach out to us today, and let’s work together to enhance your productivity with cutting-edge grinding technology. Your success starts with TSG!

- tsgmc@naver.com

- +82-55-286-5586

Upgrading Precision, Extending Machine Life

At TSG, we specialize in retrofitting and upgrading grinding machines to restore precision, improve efficiency, and extend the lifespan of your equipment. Our retrofit services cover centerless grinders, double disk grinders, internal grinders, and external grinders, ensuring that even aging machines perform like new.

Precision Restoration

Slide grinding, scraping, spindle bearing replacement, and overall accuracy recovery.

Custom Machine Modifications

Developing and installing new component supply systems to optimize workflow.

Mechanical & Electrical Upgrades

Converting hydraulic systems to Fanuc NC, replacing electrical components, and integrating servo motors with ball screws for enhanced performance.

By modernizing outdated equipment, TSG helps businesses reduce downtime, increase production efficiency, and minimize costs compared to purchasing new machines. Whether you need a full-scale rebuild or targeted enhancements, our expert team ensures your grinding machines meet today’s precision and performance standards.

Experience the benefits of machine retrofitting with TSG—your trusted partner in grinding technology.

Enhance Performance, Minimize Costs, and Optimize Productivity

Our retrofitting solutions provide precision restoration comparable to new machines, while transitioning from hydraulic to NC control ensures more accurate and repeatable settings.

- Maximize productivity with minimal investment

- Stabilize quality with precision comparable to new equipment

- Quantify settings by converting from hydraulic control to NC control

- Eliminate hydraulics for a cleaner workspace

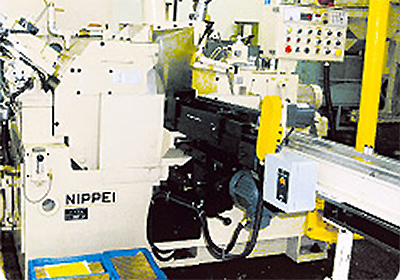

- Automate with the addition of the latest Auto Loader

Enhance Performance, Minimize Costs, and Optimize Productivity

Our retrofitting solutions provide precision restoration comparable to new machines, while transitioning from hydraulic to NC control ensures more accurate and repeatable settings.

Step 1: Disassembly, Cleaning, and Coating

The retrofit process begins with a complete disassembly of the machine to inspect all components thoroughly. We perform deep cleaning to remove accumulated debris, oil, and contaminants, ensuring a fresh foundation for refurbishment. Finally, we apply high-quality coatings to protect surfaces from wear, corrosion, and environmental factors, restoring the machine’s appearance and durability.

Step 2: Grinding, Scraping, and Assembly

Once cleaned and coated, precision grinding and scraping are performed to restore accuracy to factory specifications. Our experts meticulously hand-scrape key surfaces to enhance alignment and precision. After restoration, the machine is carefully reassembled, incorporating upgraded components such as ball screws, servo motors, and NC controls for improved performance.

Step 3: Completion, Inspection, and Test Run

Before delivery, every machine undergoes a rigorous inspection process to ensure all components function flawlessly. We conduct final precision testing and adjustments, followed by a comprehensive test run to verify accuracy, stability, and operational efficiency. This final step guarantees that the retrofitted machine meets or surpasses its original performance, ready for seamless reintegration into your production line.