super finishing machines

- home

- product

- super finishing machines

service menu

recent posts

Get in Touch with TSG

Reach out to us today, and let’s work together to enhance your productivity with cutting-edge grinding technology. Your success starts with TSG!

- tsgmc@naver.com

- +82-55-286-5586

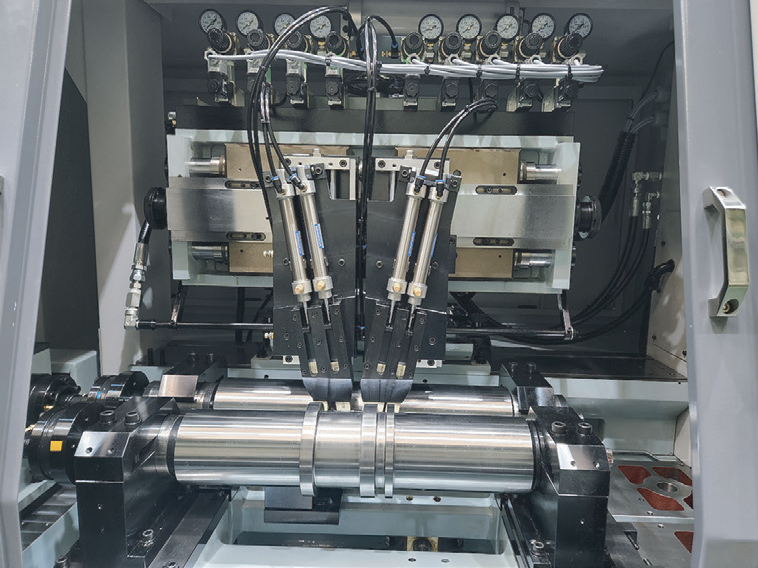

TRS-500ST & TRS-500I-Super finishing machine

The TRS-500ST & TRS-500I Super Finishing Machine are engineered for multi-step workpieces, delivering precise and uniform surface finishing even under complex processing conditions. With the ability to perform crowning super finishing on both ends, it ensures flawless surface profiles across varying dimensions.

- Super finishing for the multistep workpiece

- Crowning S/F at both ends

- Continuous S/F even workpiece supplying intermittent

- Stone wear detacting

specifications

| ITEM | TRS-500ST | TRS-500I | |

|---|---|---|---|

| Working range | Out diameter | Ø2 ~ Ø60mm | Ø2 ~ Ø60mm |

| Length | Max. 500mm | Max. 500mm | |

| Workpiece supplying | Thru-feed (Feed roll) | In-feed (Drive roll) | |

| Oscillation | Slide | Air Bearing Slide | Air Bearing Slide |

| Stroke | 0 ~ 3mm (Cam Exchange) | 0 ~ 3mm (Cam Exchange) | |

| Frequency | 100 ~ 2,000cpm (Inverter Control) | 100 ~ 2,000cpm (Inverter Control) | |

| Stone head | Stone pressure | Air cylinder | Air cylinder |

| Unit | 6 Heads | 4 Heads | |

| Feed roll | Out diameter | Ø70 ~ Ø110mm | Ø70 ~ Ø110mm |

| Shape | Hyperbolic curve feed roller | Parallel drive roller | |

| Motor | Feed box | 2.2kw, 4p | 2.2kw, 4p |

| Oscillation | 0.75kw, 4p | 0.75kw, 4p | |

| Floor size | 1,580 x 990mm | 1,580 x 990mm | |

| Weight | 2,500kg | 2,500kg | |

Thru-feed super finishing for workpieces with multiple steps

- Workpieces can go through stones parallel

Infeed super finishing that processes only a portion of the workpiece

- Max four super finishing stones available

TRS-500 / 660 / 660R-Super finishing machine

The TRS-500 / 660 / 660R Super Finishing Machines deliver high-precision surface quality at a competitive cost, making them ideal for manufacturers seeking both performance and value. Equipped with a hyperbolic curve feed roller, these machines allow workpieces to pass through the stones in perfect parallel, ensuring uniform and consistent finishing.

- Hyperbolic Feed-roll usage – Grinding stone and product are processed parallel

- Grinding stone wear detection

- Air bearings are used symmetrically left, right, up and down – mutually complementary in case of partial wear

specifications

| ITEM | TRS-500 | TRS-660 | TRS-660R | |

|---|---|---|---|---|

| Working range | Out diameter | Ø2 ~ Ø60mm | ||

| Length | Max. 500mm | Max. 660mm | Max. 30mm | |

| Workpiece supplying | Thru-feed (Feed roll) | |||

| Oscillation | Slide | Air Bearing Slide | ||

| Stroke | 0 ~ 3mm (Cam Exchange) | |||

| Frequency | 100 ~ 2,000cpm (Inverter Control) | |||

| Stone head | Stone pressure | Air cylinder | ||

| Unit | 6 Heads | 8 Heads | ||

| Feed roll | Out diameter | Φ70 ~ Φ110 | Φ120 ~ Φ180 | |

| Shape | Hyperbolic curve feed roller | Feed roll for tapered roller | ||

| Motor | Feed box | 2.2kw, 4p | 3.7kw, 4p | |

| Oscillation | 0.75kw, 4p | 1.5kw, 4p | ||

| Floor size | 1,580 x 990mm | 1,580 x 990mm | ||

| Weight | 2,500kg | 3,200kg | ||

- Super Finishing of Feed Roller is possible by transporting with specially processed rollers with a spiral barrel, enabling high efficiency and high precision taper processing.

- Depending on the shape of the roller, crowning processing is also possible.

Hyperbolic curve feed roller

- Superfinishing the outer diameter of the cylindrical products

Special Feed Roller with Spiral Grooves

- Superfinishing the outer diameter of the tapered roller